M-TS060 fiberglass thermally conductive adhesive tape are mostly used for bonding heat dissipation fins, microprocessors and other power consumption semiconductors. This type of adhesive tape possesses ultimate bonding strength with low thermal impedance, with which in effect can be able to replace the method of lubricating grease and mechanical fixing.

Features

Good thermal conductivity

High bond strength to a variety of surfaces double sided pressure sensitive adhesive tape.

High performance, thermally conductive acrylic

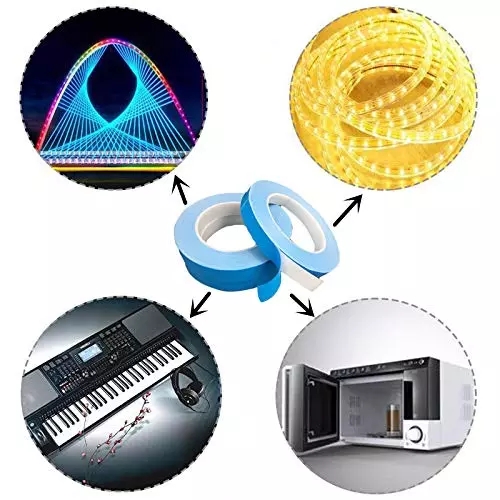

Applications

l Mount heat sink onto BGA graphic processor or drive processor.

l Mount heat spreader onto power converter PCB or onto motor control PCB.

l Can be used instead of heat cure adhesive, screw mounting or clip mounting.

Product Configuration

l Sheet sizes : 1040(or 1240)mm×25M/50M

l 0.15~0.5mm thickness optional 0.15~0.5mm

Properties

Property |

M-TS060-015 |

M-TS060-020 |

M-TS060-025 |

Unit |

Test Method |

Backing Type |

Fiberglass | 一 | 一 | ||

Color | White | Visual | Visual | ||

Thermal conductivity | 0.2-0.6 | W/M-K | ASTM D5470 | ||

Temperature range | -20~120 | ℃ | EN344 | ||

Thickness | 0.15±0.03 | 0.20±0.03 | 0.25±0.03 | mm | 一 |

Compressive strength | ≧2 | ≧2.5 | ≧3 | K v/mm | ASTM D149 |

Thermal Impedance @50psi | 0.7 | 0.9 | 1.1 | ℃- in2/W | ASTM D5470 |

Temperature range | -20~120 | ℃ | EN344 | ||

Peel Adhesion | >1000(Steel,lmmediate) | g/inch | PSTC-1 | ||

| >1200(Steel after 24 hrous) | g/inch | PSTC-1 | |||

| Holding Power | >48(1000G*25℃) | H/inch | PSTC-7 | ||

| >48(1000G*80℃) | H/inch | PSTC-7 | |||

Suggested Use of Pressure

| Pressure | Temperature | Time | 一 | 一 |

| 10psi(0.069MPa) | 25℃ | 20sec | 一 | 一 | |

| 10psi(0.069MPa) | 50-75℃ | 5sec | 一 | 一 | |

| Shelf Life | 12 Months(Indoor Temperature should be 25℃ RH:65%,and keep ventilated and dry) | 一 | 一 | ||

Q:What’s the thermal conductivity test method given on the data sheet?

A: All the data in the sheet are tested out by the third party. ASTM D5470 is utilized to test the thermal conductivity.

Q: How to find a right thermal conductivity for your application?

A: It depends on the watts of power source, ability of heat dissipation. For any customers, please contact us for the technical support.

Q: Are thermal pads reworkable?

A: It’s depend on the application and the pad being used. Thermal pads have been reused before, however,it’s up to the judgment of product designer, to see whether the pads could withstand reuse.

Q:Will the heat make the thermal pads softer?

A: ShoreC 20~80 ,there is no significant change in the hardness of thermal pads, as gap filler.

Q: What’s the tolerance for the thickness?

A :Normally ±0.1mm.

Q: Are the thermal pads electrical insulating?

A: Yes, all thermal pads are electrically isolated.

Q: What’s the shelf life for thermal pads?

A: Shelf life for thermal pad is one year after the date of manufacture. For the pads with adhesive, the shelf life is 6months after the date of manufacture. After these dates, all the characters should be retested.

Q: Can the thermal pads be with fiberglass?

A: YES, we could have thermal pads with fiberglass center to improve customer specific requirements for the tensile strength.M-TS series has fiberglass on its surface, all other models will be made at your requirement.