Ball valve installation&application instruction

1.Range of application

The ball valve is mainly used for cutting off, distributing and changing the direction of the flowmedium in the pipeline. To prolong the service life of the ball valve, full open and full close are highlysuggested.

2.Main technical parameters of the product

2-1. we select high quality cooper material and apply hot forging process in the production process.2-2. The main working medium are wter,il,gas,etc.

2-3. working temperature range from -10'Cto 120C

2-4. each nominal working pressure of our ball valve are 2. 5Mpa,2.0Mpa and 1.6Mpa

3.Installation manual

3-1. For pipe thread connection type ball valve,we should make sure the pipe being vertical againstthe end surface of the valve body when tighten the connection part.our special warning is that weshould only wrench the octagonal at the same end of body instead of the other side to avoid

deformation so as to affect its normal open function.

3-2. For internal thread type ball valve,we should control the length of the external thread at the pipeend in case deformation of the valve body caused by the external thread's aqueezing the surface ofthe internal thread so as to affect leakproofness

3-3. When connecting the pipe thread type ball valve with pipe thread,the internal thread can beeither tapered pipe thread or cylindrical pipe thread,but the external thread must be tapered pipethread,otherwise it will cause leakage due to loose connection.

3-4. When intallilgn the pipe thread type ball valve,the sealing material must be clean.

3-5. Such obstacles as wall,coupling nut and pipe should not be placed inside the open/close range .3-6. When the ball valve handle is parallel to the body,it is open,otherwise,it is close.

3-7. The working medium should not contain particles,corrosive gas or liquid

3-8. PP-R ball valve installation instruction:

3-8-1. Remove the coupling nut,PP-R pipe and O-ring from the valve body

3-8-2. Pull the coupling nut on the pipe in the original direction

3-8-3. join the PP-R flange with PP-R pipe with a hot fusion machine.Pull the O-ring in thePP-R flange when it cooled down.Last,tighten the coupling nut with valve body.

Outer wire brass faucet source factory direct sales

| Name | Brass Lockable Bibcock Tap |

| Application | General |

| Temperature Of Media | Normal Temperature |

| Power | Manual |

| Port Size | 1/2"-1" DN15-DN25 |

| Standard Or Nonstandard | Standard |

| Need Customized | 3000 PCS |

| PN | 16 |

| Free Sample | Yes |

| Port | Ningbo |

| Material | Brass |

| Pressure | Low Pressure |

| Media | Water |

| Structure | BALL |

| Main Material | Hpb 58-3 Brass |

| In Stock | No |

| Handle | Aluminum |

| Certificate | ISO 9001 2008 |

| Working Medium | Water |

DATA

|  |

|  |

Click for more information

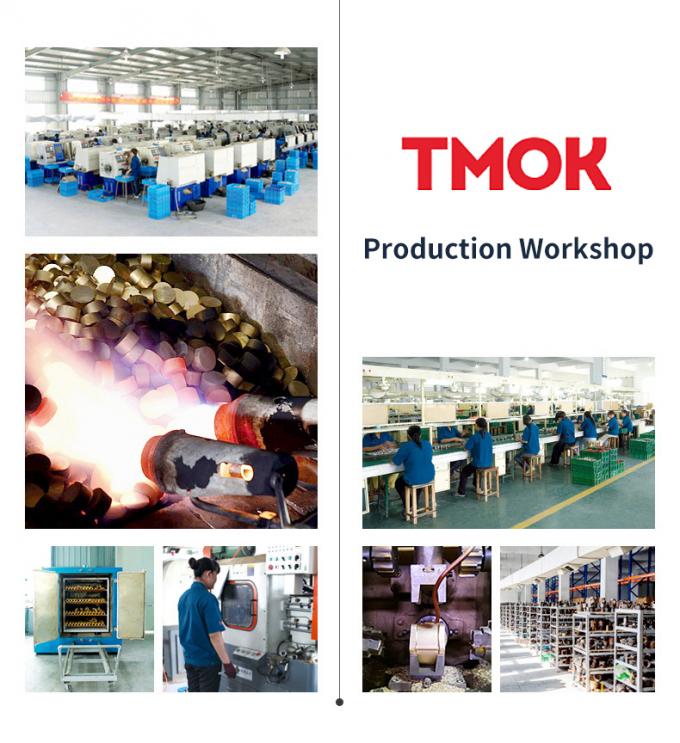

Q.How to request a manufacturing quote from TMOK?

A.Simply call or sand us E-mail with your purchase request.Be sure to include all accessories in your request for quote.

Q.What are your quality control procedures? A.TMOK adheres to strict quality control procedures that begin with product design and carry through to the end of the

production process using state-of -the-art quality control equipment .As an added measure,all clients receive production

samples for approval.

Q.How are orders packed and shipped? A.For custom order,TMOK can design full-color custom packaging to match your brand ,if requires .Most shipments

include boxes packed inside an outer carton and placed on a wooden pallet.

Q.Are there any special requirements for OEM purchases? A.Yes.TMOK requires proof of trademark registration in order to print or emboss your trademark onto the product or

packaging.

Q.Do TMOK products come with a warranty? A.Yes.TMOK backs our products100%.That's why we offer 3-year product life guarantee ,and a generous1 year

warranty on al purchases that begins with the bill of lading