Product Introduction of Magnesium iron spinel brick

The magnesia-iron spinel brick is compounded with iron-aluminum spinel and adopts special production technology to ensure that Fe in the product exists in the form of Fe2+, so that the product has good adhesion to kiln skin, corrosion resistance and flexibility. Magnesium-iron spinel brick is an ideal chrome-free basic refractory material for cement rotary kiln firing zone.

Application site of Magnesium iron spinel brick

ZJMI magnesia-iron spinel brick is suitable for all kinds of cement rotary kiln firing zone, transition zone and cooling zone. Selecting high-quality refractory materials, hanging the kiln skin, and using fuels that meet the requirements to slow down chemical erosion are the key factors to prolong the service life of the rotary kiln. ZJMI magnesia-iron spinel brick is your best choice.

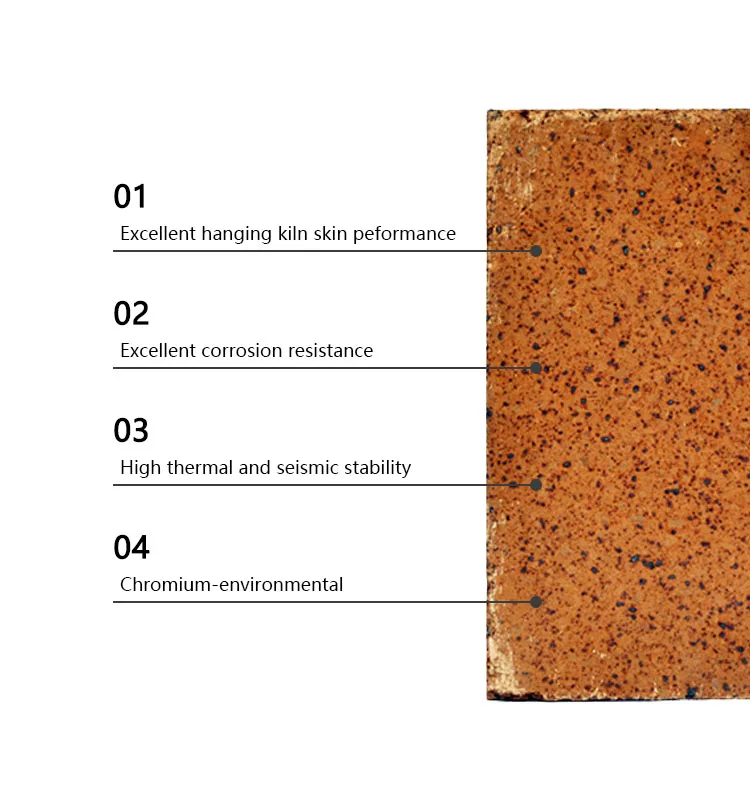

Features of Magnesium iron spinel brick

Zhenjin Company was the first in China to develop a chrome-free and environmentally friendly magnesia-iron spinel brick. This product is based on magnesia and iron-aluminum spinel as the main materials, and by introducing active spinel into the matrix components, The product forms a network-like spinel structure during the sintering process. Our products are widely recognized in the cement industry.What are the characteristics of magnesia-iron spinel bricks?

1,High compressive strength

2,Good thermal shock stability

3,Good flexibility

4,High softening temperature under load

5,Easy to stick kiln skin

Process of Magnesium iron spinel refractory brick

Packing and Shipping

Wooden pallet with plastic film or as your request.

1. The sturdy packaging protects the goods from any possible damage during transportation.

2. Sturdy packaging and overall filling to prevent the box from shaking and vibrating.

3. Take the necessary precautions to prevent the goods from being stolen or exposed to rain.

4. We will deliver the goods on time, with guaranteed quality and quantity, in full accordance with the contract and customer requirements.

Real Gold gets your cooperation and support with superb technology, excellent product quality and service. Continuing to provide quality services is our unremitting pursuit.

Our customer

Our products are exported to South Korea, Japan, the United States, Canada, Chile, Mongolia, Cambodia, Angola and other international markets. Our products have won the trust and praise of users for their stable performance, excellent quality and exquisite craftsmanship.

Company Profile

Zhengzhou Zhenjin refractory material CO., Ltd. founded in 1985, is located in Xinmi City, Henan Province, China's refractory production base, covering an area of about 70,000 square meters, is a manufacturing enterprise integrating research and development, production, sales, international trade and technical services. The company is committed to cement industry, glass industry, building materials industry, non-ferrous smelting and metallurgy industry refractory products to provide, construction and installation of personalized services.

Zhengzhou Zhenjin refractory material CO., Ltd. has long been focusing on the research and development and production of high-quality refractories. At the same time, it has also developed and produced magnesia-aluminum spinel bricks, magnesia-iron tip Refractory bricks such as spar bricks have successively created a number of safe use records in the cement industry.

The company's products are exported to Greece, South Korea, Japan, Canada, Chile, Mongolia, Cambodia and other international markets. The products have won the trust and praise of users for their stable performance, excellent quality and exquisite craftsmanship.

Our company has always adhered to the business policy of "customer interests first", adhered to the corporate vision of "real gold is not afraid of fire, and built a century-old store", aiming at international refractory production standards, integrating resources, and further enhancing the company's refractory manufacturing. core competitiveness in the industry.

Our Service

Pre-sale Service:

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

4.Training periodically high qualified service technician.

After-sales Service:

1.Highly inspecting equipments in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3.Assisting our clients for foundation construction of equipments;

4.Dispatching engineers to install and debug equipments;

5.Training the first-line operators on site;

6.Regularly visit clients to solve production problems Providing life-long maintenance service

7.Providing technical exchanging.

FAQ

Q1 : How can you control your quality?

A1 : For each production processing, ZhenJin have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods.

Q2 : What is your lead time?

A2 : It usually needs about 15- 20 days after receiving the PO.

Q3 : Can we visit your company?

A3 : Yes, surely. You are very welcome to China and we will be honored to have a customer and friend.

Q4 : What is the warranty of your products?

A4 : Our products have at least 1 year warranty,if any quality problems,we will take responsibility of the cost of the shipment and the replacement.

Q5. What's your payment terms?