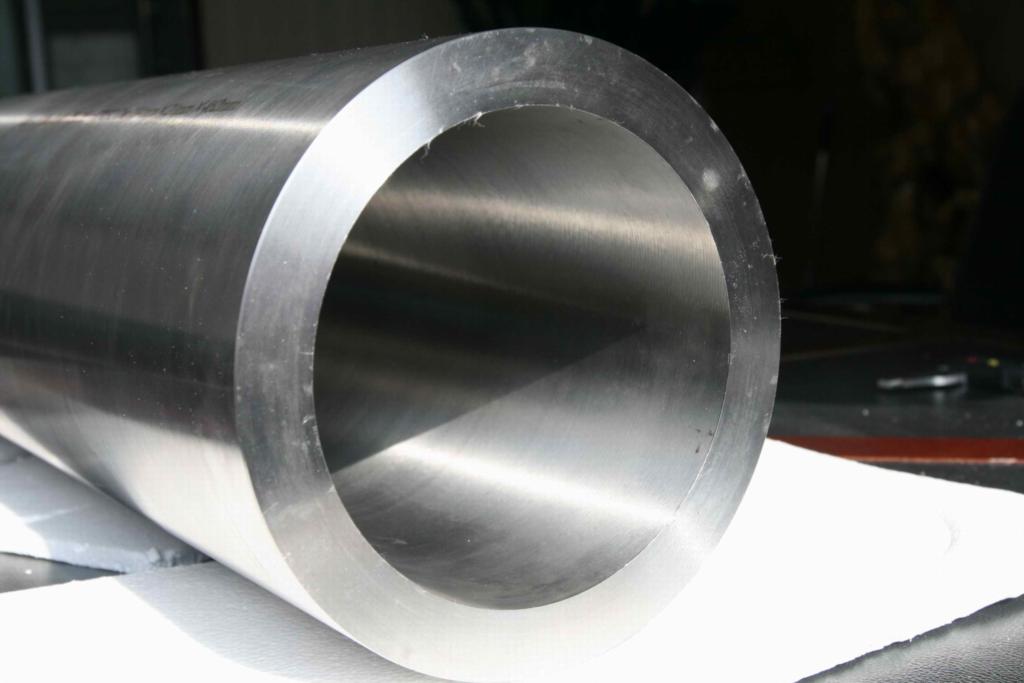

Titanium tubings are delivered in straight lengths or as U-bent tubing. Titanium spiral tubing, titanium capillary tubing are available if required. All the Titanium Tubing offered by us will pass a strict test process.

Titanium Tube Features

Low density, high specific strength, excellent corrosive resistance, no rust, good thermal stability, good thermal conductivity, biological features, plasticity.Titanium Tube Applications

Industry field, aerospace, architectural, automotive, biomedical, chemical processing, marine, military, oil, tooling, racing.

Heat exchangers and condensers

All kinds of the corrosive fluid transmission pipeline system

Titanium bicycle tube, automobile exhaust pipe

Offshore aquaculture

Inspection & Testing of Titanium Tube

Ultrasonic testing, electric non-destructive testing, flaring testing, hydrostatic testing, flattening testing, visual surface inspection, dimensional inspection, tensile properties inspection, and chemical elements analysis.

Titanium Tube Advantage

First-class product, reasonable price, fast delivery.

100% Ultrasonic Test (UT), 100% Eddy Current Test(ET), 100% Pneumatic Test. 100% Hydraulic Test.

Technology Data Sheet of Titanium Tube

| Grade | Element Composition,% |

|---|

| Ti | Al | V | Fe | C | N | H | O | Other,Max |

|---|

| Grade 1 | Balance | | | 0.2 | 0.8 | 0.03 | 0.015 | 0.18 | 0.4 |

| Grade 2 | Balance | | | 0.3 | 0.8 | 0.03 | 0.015 | 0.25 | 0.4 |

| Grade 3 | Balance | | | 0.3 | 0.8 | 0.05 | 0.015 | 0.25 | 0.4 |

| Grade 4 | Balance | | | 0.5 | 0.8 | 0.05 | 0.015 | 0.4 | 0.4 |

| Grade 5 | Balance | 5.5-6.75 | 3.5-4.5 | 0.4 | 0.8 | 0.05 | 0.015 | 0.5 | 0.4 |

| Grade 7 | Balance | | | 0.03 | 0.8 | 0.03 | 0.015 | 0.25 | 0.4 |

| Grade 9 | Balance | 2.5-3.5 | 2.0-3.0 | 0.3 | 0.05 | 0.02 | 0.015 | 0.2 | 0.4 |

Titanium Tubing Grades Guide

CP grade 1 is the softest titanium with the highest ductility, good cold formability, which gives Titanium grade 1 an excellent resistance from mild to high oxidation. Commercially Pure Titanium grade 1 is one of the softest and most ductile grades, exhibiting the most outstanding formability. It also has excellent welding properties and high impact toughness. Titanium grade 1 is designated as UNS R50250.

CP grade 2 is used most widely in commercially pure titanium. Titanium grade 2 has moderate strength and excellent cold-forming properties. Titanium grade 2 is designated as UNS R50400. Thanks to its varied usability and wide availability, grade 2 Titanium is called the "workhorse" of the commercially pure titanium industry. It is "unalloyed" titanium offering an excellent balance of strength and ductility.

CP grade 3 is almost only used in the pressure vessel. Grade 3 titanium has excellent corrosion resistance.

Alloy grade 5, Ti-6Al-4V, is most widely used in titanium alloys because of its comprehensive mechanical, physical, and chemical properties. Titanium 6Al-4V, Titanium grade 5 alloy (UNS R56400) is the most widely used titanium grade. Titanium grade 5 is a two-phase α+β titanium alloy, with aluminum as the alpha stabilizer and vanadium as the beta stabilizer. Grade 5 titanium has good welding and production characteristics.

Alloy grade 23, Ti-6Al-4V ELI (Extra Low Interstitial) is designated as UNS R56401, and Titanium grade 23 has a superior damage tolerance to other alloys. These benefits make Titanium grade 23 the ultimate dental and medical titanium grade.

Titanium 8Al-1Mo-1V is a near Alpha Alloy that is primarily designed for use at elevated temperatures - up to 455 degrees centigrade. It offers the highest modulus and lowest density of all Titanium alloys. It has good creep strength, and it's weldable by the inert gas fusion and resistance welding processes.

We focus on supplying high-quality Titanium Tubing to worldwide customers at competitive prices.

Whether you are looking for seamless titanium tubing, titanium welded tubing, titanium spiral tubing, titanium tubing stub ends, or titanium screwed fittings, we can provide you.